Klopman fabrics made with TENCEL™ Lyocell fibres are derived from sustainably grown wood and produced in an environmentally responsible, closed-loop production process, which transforms wood pulp into cellulosic ¬fibres with high resource effi¬ciency and low ecological impact.

Klopman fabrics made with TENCEL™ Lyocell fibres are derived from sustainably grown wood and produced in an environmentally responsible, closed-loop production process, which transforms wood pulp into cellulosic ¬fibres with high resource effi¬ciency and low ecological impact.

Fabrics made with TENCEL™ Lyocell fibres in combination with recycled polyester yarn guarantee comfort, image and durability, while contributing to better care for the planet and its future.

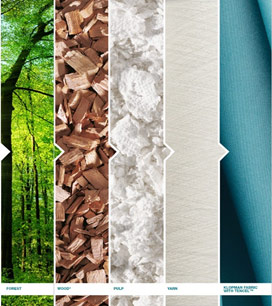

How is Lyocell made?

TENCEL™ Lyocell has gained a good reputation for its environmentally responsible closed loop production

process, which transforms wood pulp into cellulosic fibres with high resource efficiency and low ecological

impact.

This solvent-spinning process reuses the solvent at a recovery rate of more than 99%, as well as recycling

water used in the process.

All the TENCEL™ fibers used in our range are carbon neutral.

By reducing carbon emissions and using renewable energy during production, TENCEL™ Lyocell goes beyond carbon offsetting to lower its carbon footprint, offering carbon-zero products certified as CarbonNeutral® products by Natural Capital Partners.

Through the choice of carbon-zero TENCEL™ Lyocell fibres, and buying clothing made of TENCEL™ fibers, you contribute to reducing climate impact.

Carbon-zero TENCEL™ lyocell fibres have a certified carbon-neutral footprint, supporting actions against global warming in line with UN Sustainable Development Goals. Carbon-zero TENCEL™ lyocell fibres have been developed based on three pillars:

- reducing production emissions

- using renewable energy

- supporting verified global carbon reduction projects.

TENCEL™ and REFIBRA™ are trademarks of Lenzing AG.

DISCOVER OUR ![]()