Fabrics made with recycled polyester

Polyester is now the largest single fibre group used for workwear and uniforms worldwide. We are a textile company and we produce fabrics using high-quality recycled polyester yarn made from recycled materials such as plastic bottles.

Using PET clear plastic bottles as the raw material means making ethical, sustainable use of thousands of tonnes of waste plastic which might otherwise end up in landfill. Fabrics made with recycled polyester maintain all the performance characteristics you would expect from Klopman workwear fabrics. Recycled polyester fabric also helps us work towards a more sustainable world and demonstrates real respect for our environment.

The process

RECYCLED BOTTLES ARE COLLECTED, WASHED AND CHOPPED INTO BOTTLE FLAKE

BOTTLE FLAKE IS MELTED AND FORMED INTO CHIPS

CHIPS ARE MELTED AND EXTRUDED INTO RECYCLED FIBRE

FIBRE IS MADE INTO FABRICS AND THE GARMENT WE USE AND WEAR

Look what a recycled polyester fabric can do for the environment

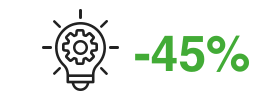

In comparison with virgin polyester, recycled polyester reduces energy and water consumption and greenhouse gas emissions.*

Recycles plastic bottles that would otherwise go into a landfill: it can take 1000 years for a plastic bottle to biodegrade

Reduces energy consumption by over 45% Vs virgin polyester

Reduces water consumption by nearly 20% Vs virgin polyester

Reduces greenhouse gas emissions by over 30% Vs virgin polyester

* data based on REPREVE® Unifi, Inc. manufacturing process

Using recycled polyester lowers the carbon footprint of fabrics

|

The carbon footprint per meter of Indestructible is 3.7 kg CO₂ |

|

The carbon footprint per meter of Indestructible Recycled Polyester Organic cotton is 3 kg CO₂ |

|

This means that converting our production to Indestructible Greenwear™ would save 5.250.000 kg of CO₂ |

This is equivalent to:

A distance of 317,197,002 km (the earth circumference is 40,075 km)

A total amount of 36,485,859 washing cycles at 60°C

The carbon sequestration of 1,757,109 beech trees

DISCOVER OUR ![]()